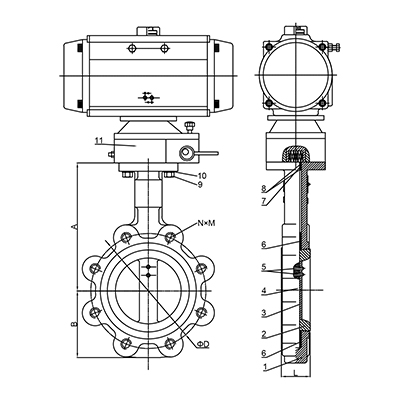

FO1-BV1LT-3P(Lugged type Butterfly Valve–Pneumatic Actuator)

●Brief

The butterfly plate has automatic alignment, which realizes the small interference fit between the butterfly plate and the valve seat. Phenolic back seat has the characteristics of no falling off, tensile, leak proof and convenient replacement. Due to the seat sealing surface and the back, As a result, the deformation of the valve seat is reduced.

●Features

1. The valve rod seal is not easy to deform, so as to avoid the usual valve stem leakage phenomenon. The overall support is good, stable and firm.

2. It is easy to control the torque value in a proper range. It is easy to use two section stem without pin connection. The structure is simple and compact, and the disassembly is very convenient.

APPLICATION

General Use: Water,sea water,gas, pressurized air, acids etc.

CARACTERISTIQUES GENERALES

Resilient Seat Lug Type Butterfly Valves

Design according with BS EN593/API609

Tightness in both ways.Lug type with threaded ears.

Flexible sleeve adapted to the shape of the body assures low operating torque.machined disc on periphery giving a low and regular torque.Unejectable stem. mounting flange according to ISO 5211.

CONSTRUCTION

| 1 | BODY | Cl / DI / WCB / STAINLESS STEEL |

| 2 | SEAT | EPDM / NBR / PTFE / SILICON |

| 3 | DISC | DI/ CF8 / CF8M / Al-Bc / DUPLEX STEEL |

| 4 | STEM | SS304 / 316 / 416 |

| 5 | PIN | SS304 / 316 |

| 6 | BUSHING | PTFE / BRONZE |

| 7 | O-RING | NBR/EPDM |

| 8 | BUSHING | PTFE/BRONZE |

| 9 | BOLT | STAINLESS STEEL |

| 10 | FLAT WASHER | STAINLESS STEEL |

| 11 | PNEUMATIC ACUTATOR | |

| NO. | PARTS | MATERIAL |

STANDARDS

Manufacture according to the requirements of the European directive 2014/68/EU,modulate H Face to face according to standards NF EN558 SERIE 20.ISO 5752, DIN3202. Mounting between flanges PN16 Body:24bar

Seat:17.6bar