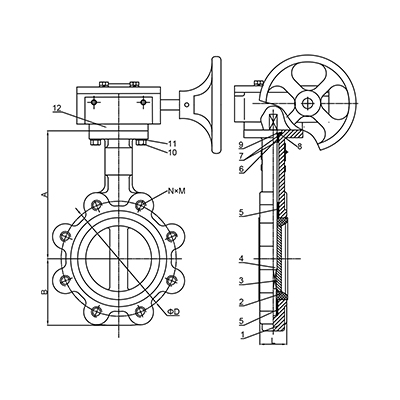

FO1-BV1LT-2G(Lugged type Butterfly Valve–Gear box Operation)

●Brief

It is easy to control the torque value in a proper range. It is easy to use two section stem without pin connection. The structure is simple and compact, and the disassembly is very convenient.

●Features

1. It can be installed in any position and convenient.

2. The sealing element can be replaced, the sealing performance is reliable, and the two-way sealing is zero leakage.

3. The sealing material has the characteristics of aging resistance, corrosion resistance and long service life.

APPLICATION

General Use: Water,sea water,gas, pressurized air, acids etc.

CARACTERISTIQUES GENERALES

Resilient Seat Lug Type Butterfly Valves

Design according with BS EN593/API609

Tightness in both ways.Lug type with threaded ears.

Flexible sleeve adapted to the shape of the body assures low operating torque.machined disc on periphery giving a low and regular torque.Unejectable stem. mounting flange according to ISO 5211.

CONSTRUCTION

| 1 | BODY | Cl/DI/ WCB / STAINLESS STEEL |

| 2 | SEAT | EPDM / NBR / PTFE / SILICON |

| 3 | DISC | DI / CF8 / CF8M / Al-Bc / DUPLEX STEEL |

| 4 | STEM | SS304/316/416 |

| 5 | BUSHING | PTFE / BRONZE |

| 6 | O-RING | NBR/EPDM |

| 7 | BUSHING | PTFE/BRONZE |

| 8 | BOLT | STAINLESS STEEL |

| 9 | PRESSURE RING | CARBON STEEL |

| 10 | BOLT | STAINLESS STEEL |

| 11 | FLAT WASHER | STAINLESS STEEL |

| 12 | WORM GEAR | CARBON STEEL / ALUMINUM |

| NO. | PARTS | MATERIAL |

STANDARDS

Manufacture according to the requirements of the European directive 2014/68/EU,modulate H Face to face according to standards NF EN558 SERIE 20.ISO5752,DIN3202.

Mounting between flanges UNI EN1092:PN10/16,ANSI150,JIS 5K/10K,BS 10 Table E. Etc.

Body:24bar

Seat:17.6bar